COVID is technically still a thing, of course. But most of us have long since shed our masks. Mandates and shutdowns have faded into the distance. It's been more than a year since we had a major spike in deaths. The pandemic — in the sense of the fundamental world-changing event — is over.

And yet, Whitworth University professor and inventor Philip Measor has been working on a way to reinvent the COVID test. Not the iffy rapid antigen test that you may have conducted at home, but the professional gold standard test that can take a long time to get results.

He thinks he can make that test smaller. And smaller means cheaper. Smaller means faster.

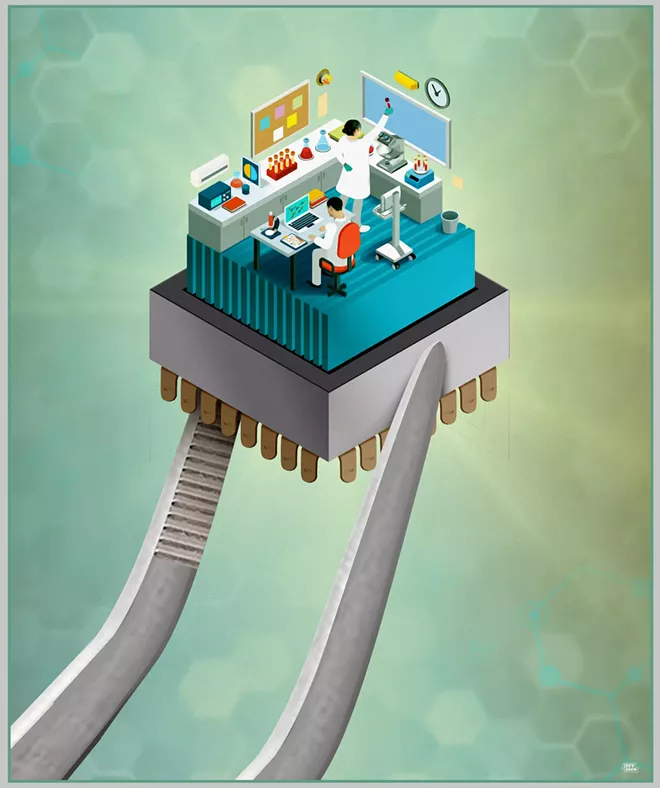

"They've shown already that you can use these types of devices to reduce the time to test from six hours to 30 minutes," Measor says. "This is the general concept of the 'lab on a chip,' trying to miniaturize functionality that can be done in an entire lab on a small chip. There's many, many different applications."

In fact, they've already done it.

To be clear, Measor and his team of Whitworth students didn't test actual COVID. It was synthetic, a completely inert version of DNA strands encoded with key pieces of the virus.

"We made probes that could detect all strains and subvariants of COVID-19," he says.

But whereas a regular PCR (which stands for polymerase chain reaction) test takes place within a device about the size of a cubic foot, Measor's device has been shrunk to less than a square inch. And the testing instrument itself? Less than 200 microns, or about the width of two human hairs.

It's not the first time he's experimented with such a thing.

"I've already done a startup company in 2010 and 2012, where I was trying to make something to address the H1N1 pandemic," Measor says.

But back then, it was far too pricey to make the kinds of semiconductor chips he was using. But one thing changed that: 3D printing. Suddenly, the economics had been flipped.

"It would be 100 times cheaper and 100 times faster to make. This is the main competitive advantage that we can use to penetrate the market," Measor says. "I could make small enough structures that I could actually make some useful devices. That's when I started the microdevices lab at Whitworth."

The smaller the testing instrument, counterintuitively, the faster the PCR test can run.

The way the PCR test works is that it uses reagents to amplify the sections of a genome that you want to study. But the more area the reagents have to work with, the longer it takes for the reagents to find the sections to amplify.

To oversimplify, imagine how long it takes an audience doing "the wave" to get around a stadium compared to how long it takes to get around a kitchen table. Or imagine how zombies can conquer a single bar much faster than an entire city.

But if you shrink the test enough, you can slash the testing time dramatically. Considering that these kinds of COVID tests were a lot more reliable than the kinds of tests you get in the mail, that could matter quite a bit. You make, say, testing outside of an important venue theoretically possible. And much more.

Here, of course, is the point where any skeptical journalist will be overcome with distraction about Elizabeth Holmes, Theranos and Bad Blood: The Silicon Valley woman who captured the heart of countless investors — and WalGreens — with the promise that just a drop of blood could be analyzed with a "MiniLab" and, within a short period of time, spit out an analysis of everything from potassium levels to Ebola.

But it was a fraud. The problem was not just that the technology was fictional, but effectively scientifically impossible — the sheer number of tests the company promised to do on a single drop of blood wasn't workable.

What Theranos was pitching was trying to do too much with such a small sample size.

"If your volume is too low, you won't have even one single copy of that virus in that sample," Measor says. "You could get a false negative."

What's different here, Measor points out, is that he's shrinking the lab size, not using less of the sample. The sample can be concentrated, but you still have the same amount of relevant material.

Even though COVID isn't as big of a concern as it was three years ago, a sequel is inevitable.

"There will definitely be another pandemic," Measor says. "It's just a matter of when. So we should be better prepared."

He already has a patent for the 3D-printed COVID test — and the other possibilities are endless.

"Not only can we detect viruses, we can detect bacteria, parasites," Measor says "You can detect it in humans, detect it in animals, and detect it in water." ♦