Wind turbines have quickly been adopted in Washington for their attractive renewable energy generated by harnessing the wind.

According to the Northwest Power and Conservation Council, Washington's first wind turbines became operational in 1998, but the first major wind turbine farm, the Stateline Wind Farm along the Columbia River Gorge, opened in 2001 and grew to more than 450 wind turbines over the next several years.

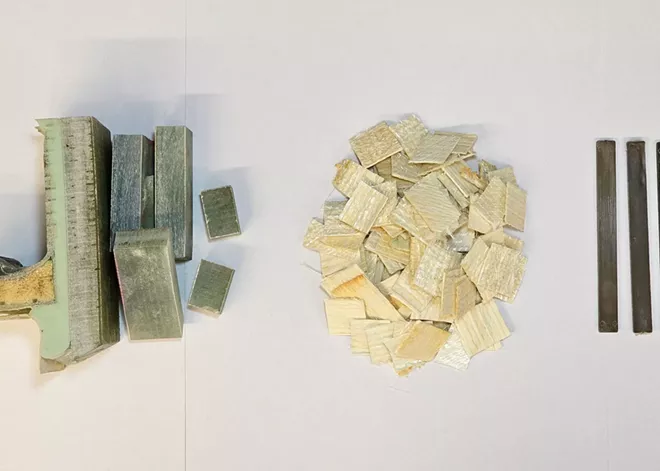

On average, a wind turbine has a 20-year lifespan, and turbine blades are constructed from fiberglass and reinforced with resin or plastic to achieve the durability needed to function under the stress of weather conditions and usage wear.

Some residents who are resistant to wind turbine farms in Washington have brought up concerns about unrecyclable wind turbine blades. They quickly point to the 1,000 turbine blades buried at the Casper Regional Landfill in Wyoming.

Many of these first-generation modern turbines are reaching the end of their lifespans — the U.S. Department of Energy expects to retire 10,000 to 20,000 turbines per year by 2040.

Researcher Jinwen Zhang at Washington State University was motivated by the need to find ways to recycle the thousands of turbines that are nearing the end of their use.

"That's why it's so urgent in the research field; we need to find an eco-friendly and economic viable solution for recycling these materials," Zhang says.

Zhang, a professor of mechanical and materials engineering, began his research at WSU in 2004 on the related work of polymer materials, with an emphasis on polymer synthesis, processing, recycling, and application development. Polymer materials can range from plastics to nylon, Teflon, and even the fibers used in bulletproof vests.

Zhang's next steps were to examine current research on recycling strategies for wind turbine blades and to determine the difficulty of recycling glass fibers.

"Wind turbines are made of very high-fiber materials, particularly glass fibers," Zhang says. "Once the product is made, it cannot be reprocessed similarly to [plastic] bottles."

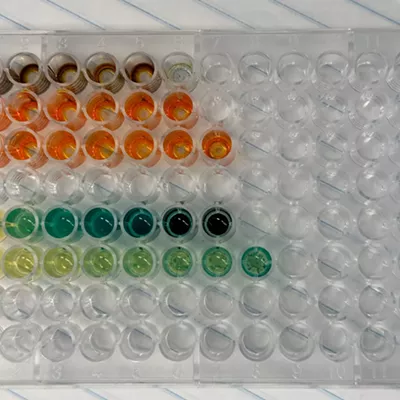

Through eight years of research, Zhang and his team developed a mild-intensity and low-toxicity solvent process utilizing zinc acetate as a mild solvent to break down pieces of turbine blades.

Zhang published his most recent research on recycling wind turbine blades in Resources, Conservation, and Recycling in April.

In this process, researchers cut the blade made of glass fiber-reinforced polymer into small, 2-inch pieces. Then, the pieces are soaked in an organic salt bath solvent and pressurized in superheated water for about two hours, which breaks down the material.

Once the materials are broken down, the recycled fibers can be compounded with a polymer resin or other thermoplastic materials like nylon. The material is turned into injection-molded plastic containing 70% recycled glass fiber-reinforced polymer.

The new composite material is much stronger and can be used for extruded materials. Zhang's research determined that the composite materials made of nylon and blade recyclable materials are three times stronger.

"There are many applications for industry use that need reinforcement," Zhang says. "So, they have a component in the cars that needs fiber-reinforced materials."

The new process is more efficient and less dependent on incorporating new materials to strengthen the recycled product, as demonstrated by other research on the same topic.

The process was successful in breaking down the materials, but Zhang says a hurdle in the research was the pressurization, which required heating the water to 200 degrees Celsius.

"One of the issues that still exists is the temperature, because at a temperature around 200 degrees Celsius, you still have to resort to the use of the pressure reactor for this process," Zhang says. "So that will still be a significant hurdle for scaling up and economic viability."

Zhang's current process doesn't allow for recycling old turbine blades into new ones because they must be made of continuous fibers to maintain blade strength, and not cut into pieces like his process employs.

He says it's also difficult to scale up the recycling process because the blades are usually made in one or two pieces and often span more than 600 feet. No facilities or chemical reaction vessels can accommodate the process that Zhang uses to recycle the materials into blades that size.

Though he's still developing a scalable process to recycle blades into other materials effectively, Zhang says placing wind turbine blades in landfills is a total waste. He thinks there are better (although expensive) methods that can still repurpose blades as material filler for other purposes, such as in concrete.

Zhang hopes that the research and development on recycling turbine blades will lead to new added value for waste materials.

If the process is simple, it will be easier to scale up and be economically viable, Zhang says.

"There is still room to improve on the process, and we are pursuing doing that at ambient pressure for this chemical recycling," Zhang says. ♦